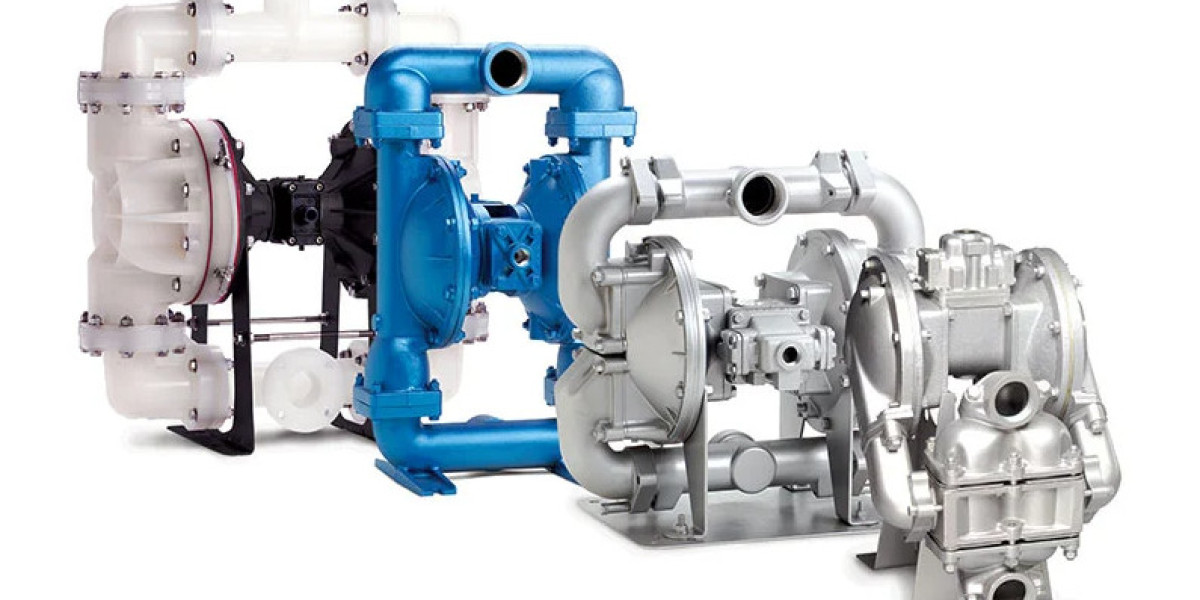

Centrifugal AOD (Air-Operated Diaphragm) pumps have become indispensable in many industrial applications due to their versatility, reliability, and efficiency. These pumps combine the principles of centrifugal force and air operation to deliver fluids efficiently, especially in situations where electricity may not be safe or practical. In this blog, we will explore the key features, working principles, and benefits of centrifugal AOD pumps, along with their applications in various industries.

What is a Centrifugal AOD Pump?

A Centrifugal AOD pump operates using compressed air to drive diaphragms, which create suction and force fluids through the system. The pump does not rely on electric motors, making it ideal for applications in hazardous environments where sparking risks are high. Its design leverages the principles of centrifugal force, ensuring that fluid is moved smoothly and efficiently through the system.

Working Principle of Centrifugal AOD Pumps

At the heart of any centrifugal AOD pump are the diaphragms. These flexible membranes are driven by compressed air to create alternating pressure. The diaphragms work in tandemwhen one expands to draw fluid in, the other contracts to push fluid out. This cyclic process enables continuous fluid movement through the pump.

The air valve system controls the movement of compressed air, alternating the pressure between two chambers that house the diaphragms. As air enters one chamber, it pushes the diaphragm outward, causing fluid to move through the pump. Once the diaphragm reaches the end of its stroke, the air valve shifts, sending air to the opposite chamber, repeating the cycle.

Key Features of Centrifugal AOD Pumps

- Air Operated: These pumps are powered by compressed air, eliminating the need for electrical power sources.

- Self-Priming: Centrifugal AOD pumps can prime themselves, making them highly efficient in various operating conditions.

- No Mechanical Seals: Since these pumps do not use mechanical seals, the risk of fluid leakage is reduced, increasing their reliability and lifespan.

- Handles a Variety of Fluids: From corrosive chemicals to viscous slurries, centrifugal AOD pumps are capable of handling a wide range of fluids, including those containing solids.

- Safe in Hazardous Environments: Due to their air-operated nature, these pumps are spark-free and safe for use in flammable or explosive environments.

Benefits of Using Centrifugal AOD Pumps

- Versatility: Centrifugal AOD pumps can handle a variety of fluids, including water, chemicals, oils, and slurries. Their ability to pump viscous and abrasive materials makes them suitable for industries such as mining, chemical processing, and wastewater treatment.

- Low Maintenance: These pumps require minimal maintenance due to their simple design, absence of electrical components, and lack of mechanical seals. This reduces downtime and operational costs.

- Portable and Compact: Many centrifugal AOD pumps are compact and portable, allowing them to be easily moved around a worksite or installed in tight spaces.

- Energy-Efficient: Since they use compressed air, centrifugal AOD pumps are energy-efficient, especially in applications where electricity is limited or unavailable.

- Self-Regulating: These pumps can self-regulate their flow rates and pressure based on the demands of the system, which enhances their operational efficiency.

Applications of Centrifugal AOD Pumps

Centrifugal AOD pumps are widely used across various industries due to their ability to handle different types of fluids and environments. Some common applications include:

- Chemical Processing: Their resistance to corrosive substances makes them ideal for transferring acids, solvents, and other hazardous chemicals.

- Mining: Centrifugal AOD pumps are used to handle slurries, including mud and slurry from mining operations.

- Oil and Gas: These pumps are perfect for transferring oils and fuels without risking fire or explosion in volatile environments.

- Food and Beverage: They are used to transfer food products, including liquids with suspended solids, such as sauces or purees.

- Pharmaceutical: In the pharmaceutical industry, AOD pumps are utilized to transfer sensitive or sterile fluids without contamination.

- Wastewater Treatment: Centrifugal AOD pumps are often employed to pump sludge, wastewater, and other treatment by-products.

Conclusion

Centrifugal AOD pumps are a powerful solution for industries requiring reliable fluid transfer in diverse and sometimes hazardous environments. Their air-operated design, coupled with the efficiency of centrifugal force, makes them a robust option for handling a variety of fluids. Whether in chemical plants, mines, or wastewater treatment facilities, centrifugal AOD pumps deliver performance with minimal maintenance and maximum safety.